Choosing natural refrigerants | Tetrafluoropropene

Choosing natural refrigerants: part 5

R1234ze Tetrafluoropropene

Natural refrigerants are a hot topic. With more and more onshore utility-based installations switching to natural gas, what’s the situation in the maritime industry? Selecting the right refrigerant is no easy task as each type has its own pros and cons. In this series of blogs we explore the most common natural refrigerants to help you decide which best suits your specific application.

In all the previous blogs we discussed pure natural refrigerants, but there are also synthetics that meet the latest environmental requirements. R-1234ze is specially designed as a replacement of R-134a but with a global warming potential around seven. This synthetic refrigerant of the fourth generation is a HFO (Hydro Fluor Olefine) and is mainly used in chillers but can also in heat pumps.

To give you a comprehensive overview we are comparing every refrigerant on the following fixed set of properties:

| Thermodynamic properties | Safety | Sustainability |

| Temperatures | Flammability | GWP |

| Pressures | Toxicity | Ozone depletion |

| Latent heat capacity | Pressure | Energy efficiency |

| Corrosive |

All starting points are the same for every refrigerant, including the temperatures below:

Evaporation temperature: -10°C

Condensation temperature: 25°C

Overheating: 20K

Subcooling: 5K

Thermodynamic properties

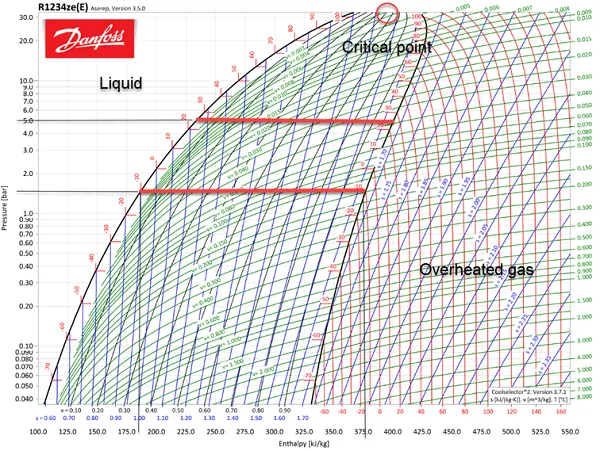

While evaporation/ condensation pressure and temperatures are not out of the ordinary, the latent heat capacity of R1234ze is lower than its natural counterparts.

- Evaporation and condensation temperature

R1234ze has a high temperature range and with a critical point above 109°C can easily be used with seawater condensers. The triple point lies at -104°C, making it suitable for both chilled water purposes. - Evaporation and condensation pressure

The pressure range is pretty low. At an evaporating temperature of -10°C the absolute pressure is around 1,5 bar; at a condensation temperature of 25°C the absolute pressure is around 5 bar. - Latent heat capacity

Latent heat values are below average. The enthalpy at the -10°C line will be around 190 kJ/kg.

Safety

R1234ze is classified as a mildly flammable refrigerant. It is labelled as A2L.

|

Safety group |

Lower toxicity |

Higher toxicity |

| High flammability |

A3 |

B3 |

| Flammable |

A2 |

B2 |

| Lower flammability |

A2L |

B2L |

| No flame propagation |

A1 |

B1 |

- Flammability

Classified as mildly flammable R1234ze can ignite under certain conditions. However, when stored at temperatures under 30°C it does not produce any flammable mixtures with air. - Toxicity

R1234ze is not toxic, however it does displace oxygen in a confined space. Measures such as proper ventilation must be applied to avoid asphyxiation. - Pressure

R1234ze has no pressure issues. - Corrosion

Inhalation, eye and skin contact needs to be avoided, R1234ze is not corrosive for the installation’s materials.

Sustainability

R1234ze has low GWP and ozone depletion values. Leakages have hardly any effect on the environment.

- GWP & ozone depletion

As the global warming potential of R1234ze is 7 it makes almost no contribution to the greenhouse effect. With the ozone depletion capacity equal to 0, emissions have no effect on the ozone layer. - Energy efficiency

The energy efficiency depends on the design at specific temperatures. For an accurate comparison we used the same temperatures value for each refrigerant as specified above. Based on these conditions the EER is 4.1. This can be improved with smart system design.

Conclusion

The synthetic refrigerant R1234ze is designed as a replacement for R134a but has a higher specific volume. Therefore, a compressor with more displacement is needed to achieve the same capacity. This means the chiller itself must be bigger/ more expensive.

Please note that the values and calculation given in this article have been simplified in order to give you a general overview of the pros and cons of this refrigerant. More specific information is needed for a detailed calculation and we strongly recommend contacting one of our engineers if you are considering the use of natural refrigerants.

Want to learn more about natural refrigerants? You can download our extensive whitepaper here.